Services

Our consistent upskilling, retraining, focus on cutting-edge technology, and extensive diversification ensures we remain far ahead of our competitors

SERVICES OVERVIEW

Diverse services offering for large commercial vessels

When booking your scheduled or emergency commercial vessel repairs, maintenance or new builds with Enlee Port Operations, you will benefit from the excellent competencies and customer-focus of our teams.

No matter what your vessel or fleet needs are, Enlee can provide a world-class solution through our diverse full marine engineering and service capabilities. In addition to our extensive range of maritime-related goods and services, you will have access to a valuable network of leading marine experts and niche specialists.

Enjoy the quality of our impeccable service and market reputation that stretches across mechanical fitting, boiler making, pipe fitting, Bureau Veritas accredited welding, flame and plasma cutting.

Marine Engineering

Our world-class engineers design & monitor tests, installations & repairs of vessels & equipment.

Ship Refurb & Repair

We work on bulk, container, LNG & gas vessels, tankers & other types. Conversions on floating storage.

Gas & Plasma Cutting

Plasma cutting is a melting process in which a jet of ionised gas at temperatures above 20,000°C is used to melt and expel material from the cut.

Industrial & Structural Engineering

Superior mechanical fitting, boiler making, pipe fitting, accredited welding, flame & plasma cutting.

Our full range of services

WORKSHOP SERVICES

- Steel and pipework

- Pipework and valves

- Boiler making

- Welding

- Mechanical fitting

- Fabrication

- Bending and shaping facilities

- Plate cutting facilities

- Milling and turning

ONSITE REPAIRS

- 24-hour emergency call-out services

- Ship repairs

- Shipwright services

- Valve overhaul services, repairs & maintenance

- General hot works

- Coded welding and boiler shop services

- Dry docking works

- Vessel refits, refurbishment & modifications

Services overview

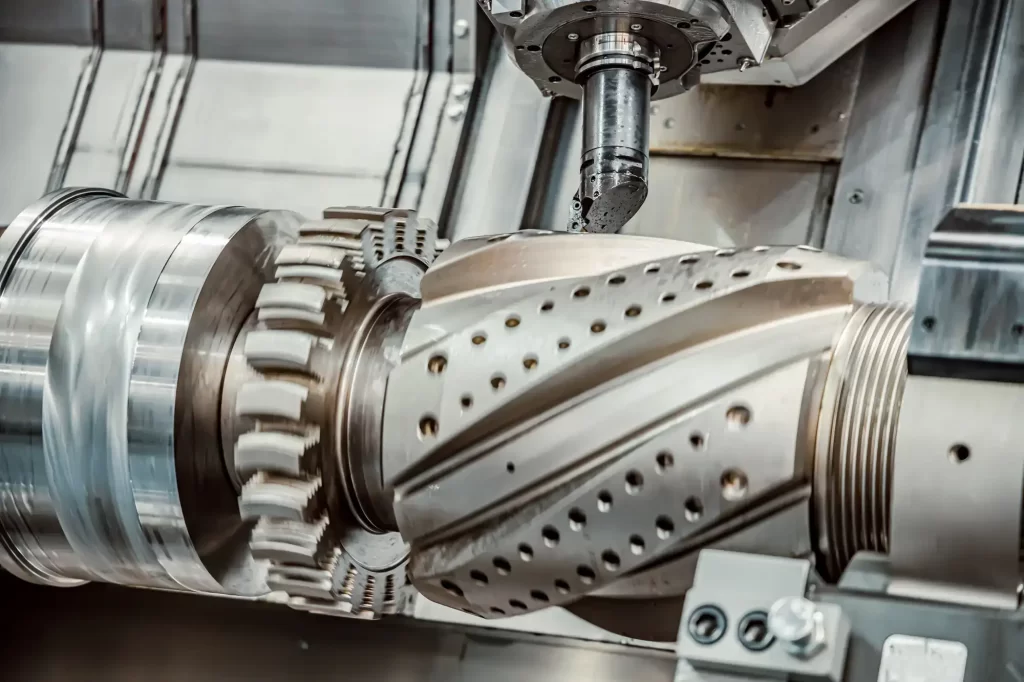

High-capacity tools and machines

Our experienced specialists can meet all special engineering designs and needs for conventional steel and heavy steel work.

Our port operations facilities are equipped with the following high capacity tools and machines:

Band saw cutting

Degree of cut: any skew cut, at any angle

Drilling

Can accommodate any aperture size up to 60 mm

Milling & Turning

Our qualified team of experts have access to every piece of specialized equipment and tool at their disposal to ensure your job is created and delivered to your exact specification and at the highest level of precision.

Gas cutting machine

Precision cutting of complex shapes to meet any customer specification

Bending and cutting machine for plates

Bending and cutting machine for plates - Can accommodate cutting thicknesses from 5 mm to 16 mm

Welding

Our port operations utilise FCAW and SMAW processes based on the structural welding code of AWS, ASME and ISO certification.

Our quality control system monitors and evaluates the daily workmanship of all our welders at every consecutive working period.

Standard Welding Procedure Specification (SWPS) – AWS B2.1-1-016-2018

Safety in Welding, Cutting & Allied Processes – ANZI Z49.1

Welding process: SMAW (ISO 111) pWPS –

AWS A5.1

Electrode specification -

AWS A5.1

E7018-1H4R

Electrode classification -

E7018-1H4R

Nr 216 DT R11 E

According to Bureau Veritas Rule Note Nr 216 DT R11 E July 2019

In the pipeline

We are in the process of

Dual PQR

Drawing up a Dual PQR according to ASME and ISO with the assistance of RBI Technical Solutions (PTY) Ltd

WPS and PQR

Drawing up WPS and PQR for welding of carbon steel plates for shipbuilding/repair work and not as a welding procedure for general fabrication with the assistance of Bureau Veritas and IACS rule requirements.

ISO 3834

Working towards attaining the ISO 3834 welding certification.

Enleeport

Use South Africa’s top commercial vessel industrial & structural engineering, mechanical & shipwright provider. Quality, ethics & environmentally conscientious.